Tag: laser

Mixology. A personal bartender.

by Adam Evenden on Jun.12, 2014, under Projects, Unpatched Tuesdays

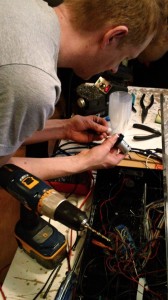

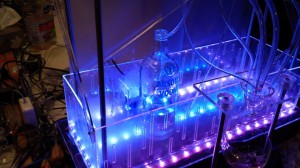

Recently one of our members decided that he would create a personal bartender in a form of a Droid bartender. This handy piece of equipment is functional and makes a great conversation piece. The bar bot is named Luma-Droid and mixes some mean drinks. Not all of these drink need to be alcohol, I am sure this Droid can can mix a mean punch as well. This handy Droid uses 4 different liquid sources to mix from 6 different drinks pre-determined programmed and dispenses at a push of one of the illuminated buttons. This is actually the second version of this little Droid. The first version did not have the ultra sonic humidifier that creates a further finished and polished look. But not every improvement is merely aesthetic. Many times when creating a project that delves into areas that is a first for anyone, creates problems and a list of things you would do differently if provided a chance. Well Eric had the chance and in the second version shown in the photos, the ultrasonic humidifier was added, as well as new pumps, reservoir for the humidifier, and for good measure a extra layer of sealing to ensure the water proofing.

Cut and Sew.

by Adam Evenden on May.07, 2014, under Projects, Unpatched Tuesdays

Several Months ago, a class mate approached me regarding a class assignment.

This is not an unusual for students to do to each other, but the subject was lasers and cutting services and where to find them.

I provided her with a few resources, and also mentioned work had one.

One thing lead to another and Several weeks later I received some Cad drawings to process for laser cutting.

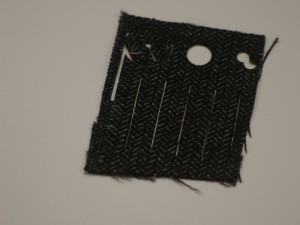

The project that I assisted her with was a tailoring assignment, cutting fabric for various embellishments.

I do have to note that some photos have been cropped down to a quarter of the original size due to respecting her intellectual property, and artistic property.

Photo of the week: Fire and Ice.

by Adam Evenden on Feb.26, 2014, under Projects

During the winter one of the members tried carving ice with the laser, with the intent to capture a little bit of Game of Thrones in ice.

This may sound both a great idea and a bad idea at the same time. The act of doing some test cutting proved this task to be more difficult than previously thought. Below you can see the results of the test cuts. The challenge was not water inside the laser, that was a simple challenge to overcome by adding a reservoir for any water that was melted and a mesh to keep the ice out of the water. The challenge with this came to be the laser itself. The power of the laser on the ice is just a bit too much for this job. This experiment became a practical demonstration of the effect of hot spots on ice in the Arctic.

The Laser is equal to the sun here, and when it heats up the ice enough for it to melt it basically creates a warm pool of water that melts the surrounding area of ice preventing any high resolution cutting. The more heated water the less of ice that remained. The laser job had to be stopped a few times to remove the excess water to achieve some of the quality of the cut in the second photo.

One snowy open house.

by Adam Evenden on Mar.24, 2013, under Unpatched Tuesdays

Comments Off on One snowy open house. :Creativity, laser, newbies, Open House, Photos, teaching, Tuesday Night Open House more...Brain Food – Double post; Raspberry Pi Cases and Train Overlord Progress.

by Adam Evenden on Aug.09, 2012, under Projects

Here we see the box for the tasty Raspberry Pi on the left, and on the right the ever advancing brain for Train Overlord.

Laser Engraver is ALIVE!

by elmood on Mar.14, 2009, under Projects

About two weeks ago Hacklab acquired a Universal Laser Systems ULS-25P laser engraver. Ted found it for sale used for a small sum. But it had broken, ancient electronics which was the reason the unit was sold. We decided that it might be fun to try building our own electronics to get the unit going again. Exactly one week ago Dan and I came into the lab in the evening and tested the laser. We made a little Arduino program to send the laser the correct control signal. Amazingly, it worked! We burned a hole quite successfully through a piece of paper. With a 25W CO2 laser it would be possible to etch and cut a lot of materials under computer control!

A bunch of us worked all last weekend and a few nights this week building electronics, learning to configure and use the emc2 CNC software, and install a place for the unit to sit and proper ventilation to extract smoke and fumes from the etched material. And I am happy to report that exactly one week after initially testing the laser we have a fully working system! Below is a video of the very first run with the laser on.

We still have more to do learning about g-code and the CNC software, calibrating laser power and so on. Also, the machine needs to be moved to its final home in the bathroom with proper ventilation. I’ll be writing a complete page about all the technical details, including schematics, firmware, photos, etc. soon. For now enjoy the video, and please check it out next time you’re at the lab or ask on IRC.